Operation and maintenance of soil centrifuge in testing

Part of the article:Release time:2021/7/13visitor sessions:3389

In order to solve the problems of heavy chemical fertilizer, light organic fertilizer, blind fertilization and excessive fertilization in the current fertilizer application, the soil testing formula fertilization technology should be widely applied in order to improve the utilization rate of fertilizer, reduce the waste of fertilizer resources, reduce agricultural non-point source pollution, protect the ecological environment and ensure the sustainable development of agriculture.

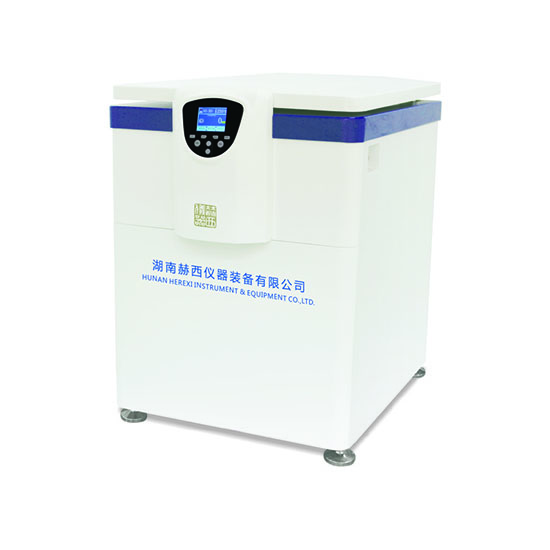

1 Necessity of centrifuges

The composition of a soil solution plays an important role in predicting the biological availability of nutrients to plants, especially when the solution concentration is expressed in terms of a single ion activity. In order to determine the activity of ion species in soil solution, it is necessary to prepare the extract which can accurately reflect the real soil solution. A centrifuge is used to prepare a soil solution.

2. Procedures for centrifuge operation

Before each test, it is necessary to check whether the speed regulating knob of the centrifuge is in zero position, whether the outer casing is intact, whether the rubber pad and the sealing apron are out of place, and the sealing apron of the door should be sealed well. After a period of use, it is necessary to apply vacuum sealing grease. If the sealing ring is found to be aging, cracking and losing elasticity, it should be replaced immediately.

The method of collecting soil samples is to obtain original samples with the ring knife of the centrifuge, and 4 repeated samples of each soil sample are taken. Soil samples were brought back to the laboratory, saturated with water for 48 hours, and then centrifuged with a high-speed refrigerated centrifuge [3]. Before centrifugation, transfer the centrifuged soil sample into a suitable centrifuge tube, and pay attention to the amount of 1~2cm away from the orifice of the heart tube, so as not to be thrown out during centrifugation.

(1) do a good job of balancing each centrifugal tube.

(2) Switch on the power supply and open the switch.

(3) Set the centrifugal speed, time and other parameters before placing the balanced sample tube.

(4) After the centrifuge is centrifuged, the centrifuge can stop working by itself before opening the boot cover and taking out the soil sample after centrifugation.

(5) Turn off the switch, cut off the power supply, and do a good job of cleaning inside and outside the centrifuge.

3 Precautions before use

3.1 Selection of centrifugal tube

When loading the prepared soil sample, it should be carried out according to the specific operation instructions of various centrifuges. According to the nature and volume of the sample to be centrifuged, the suitable centrifuge tube should be selected. When using the centrifugal tube without a cover, the sample should not be loaded too much to prevent it from being thrown out during centrifugation. Do not use significant deformation, damage or aging centrifugal tube.

3.2 balancing

A balance must be used to balance the centrifuge tube and its contents accurately. Note that when balancing, refer to the centrifuge instruction manual. The instruction manual generally has a specified range for the weight difference between the centrifuge tubes. Be careful not to exceed this specified range.

3.3 Placing of centrifugal tubes

When placed in a centrifuge tube, must pay attention to is absolutely can't load the singular pipe, when not loaded with centrifugal tube in turn, is only part of the loading, the centrifugal tube must be symmetrically placed in turn to each other, so that the force evenly distributed around the turn, so as to avoid uneven during high speed centrifugal force, the centrifugal GuanFei out of danger.

4. Matters needing attention in use

In the process of centrifuge working, the operator should not leave at will, should observe whether the instrument on the centrifuge is working normally at any time, once there is abnormal sound should be immediately shut down for inspection, and timely troubleshooting.

4.1 Precautions for turning head

The rotating head is a key part to be protected in the centrifuge. The rotating head has a certain weight and should be careful when moving to avoid collision so as not to cause scars. Each Turner has its maximum allowable speed and cumulative time limit for use. When using the Turner, it should be used within the specified speed according to the provisions on the manual. Overspeed is strictly prohibited. Each turnhead should have a use file, record the accumulated use time, if exceeds the maximum use limit of the turnhead, it must be used according to the provisions of the speed. After each use, you must carefully check the head, dry in time, do a good job of cleaning. When the head is not used for a long time, it should be protected with a layer of glazing wax.

5Precautions after centrifuge use

After the centrifuge is used, special attention should be paid not to pollute the inner cavity of the centrifuge, and pay attention not to fall into dust and be contaminated with oil. After wiping clean, it is recommended to open the top cover and keep the centrifugal chamber dry. Note that when cleaning the centrifuge, the rotor and centrifugal chamber can generally be cleaned with water or neutral detergent. Do not use acid or alkaline solutions or solvents that are corrosive to materials.

6 Other matters needing attention

1 The centrifuge must be placed on a flat and firm ground or the test bench, and tilt is not allowed.

2 The centrifuge should keep a certain distance from other electrical equipment as far as possible. Good grounding measures should be taken and regular inspection should be carried out to ensure safety.

3 After the centrifuge starts, if there is abnormal noise and vibration, it should be shut down immediately.

Latest Herexi News

- Hunan Herexi Join Hands The hunan science & equipment society

- Jinganzhang,I'm come; CISILE, I'm Here!

- Beijing Scientific instruments show & CISILE 2013 exhibition

- The training in Chengdu of Herexi series product

- The Algeria clients to visit centrifuge' production process of Herexi instrument

- Vacuum concentrator centrifuge celebrated the victory of China council for science association council board of directors

- High-speed centrifuge congratulations on successful launch of the shenzhou 10.

- analytica China at ShangHai 2014

- The world Unique Moisture Analyzer lunched

- Exhibition Announcement in the Second Half of 2016

Latest industry News

- Centrifuge rotor

- About the PRP centrifuge

- Laboratory Centrifuges

- Benchtop Centrifuges

- About the floor standing high speed centrifuge

- LCD centrifuge

- Oral special centrifuge/CGF centrifuge

- African swine fever centrifuge

- 5 Tips for Choosing the Right Centrifuge for your Lab

- The right choice of centrifuges, you can not ignore some of the problems!

kevin@hexiyiqi.com

kevin@hexiyiqi.com  0731-88142288

0731-88142288