Centrifuge application in the pharmaceutical

Part of the article:HerexiRelease time:2019/3/26visitor sessions:3459

As one of the indispensable equipment in the pharmaceutical industry, centrifuges have been developing very vigorously. Centrifuges are widely used in the medical field, and blood separation, virus research, DNA research, and drug purification are widely used in centrifuges. Centrifugation is the use of the powerful centrifugal force generated by the high-speed rotation of the centrifuge rotor to accelerate the sedimentation velocity of the particles in the liquid, and separate the sedimentation coefficient and the buoyant density of the sample.

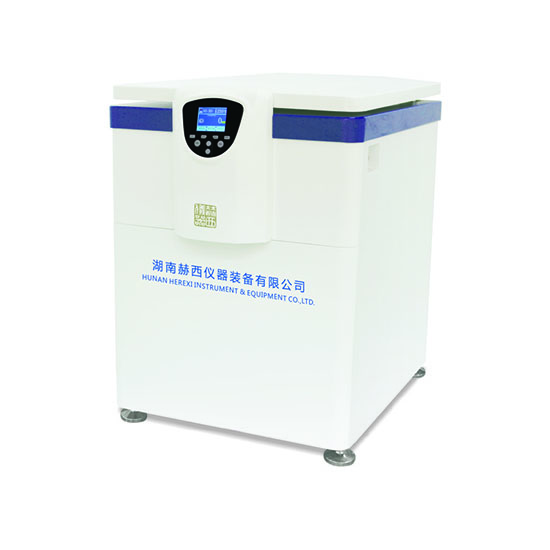

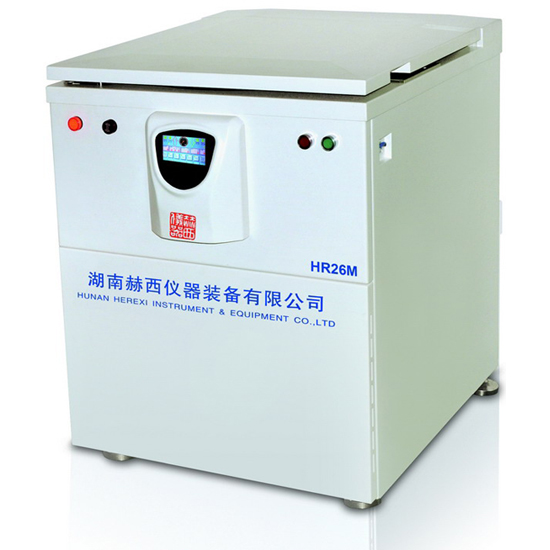

The pharmaceutical centrifuge has the characteristics of good adaptability, high degree of automation, stable operation, strong processability, good corrosion resistance, good operating environment, complete and reliable safety protection device and beautiful appearance. The centrifuge used in the refining process such as drug purification is a general low-speed centrifuge, and the rotation speed is below 4000 rpm, and the processing capacity is large.

There are many types of medical centrifuges:

According to the purpose of separation, it can be divided into: laboratory medical centrifuge and industrial pharmaceutical centrifuge.

According to the structure, it can be divided into: desktop medicine centrifuge and floor-standing medical centrifuge.

According to the temperature control can be divided: frozen medicine centrifuge and centrifuge.

According to the separation component, it can be divided into: solid-liquid separation medical centrifuge and liquid-liquid separation medical centrifuge.

Divided by capacity: micro-medicine centrifuge, small-capacity medical centrifuge and medical large-capacity centrifuge.

The high-speed centrifuge uses DC brushless motor, maintenance-free; microcomputer control, pre-selectable speed, time, centrifugal force, liquid crystal display, easy to operate; 10 kinds of lifting rate to choose from, can be quickly started, fast shutdown; stainless steel container room, electronic Door lock, early warning and alarm function, multiple protection, safe and reliable.

The technology of this kind of centrifuge is relatively simple. Generally, the multi-use zone centrifuge is used. The zone centrifuge separates and collects cells, viruses and DNA molecules according to the density and gradient of the sample solution. The sample loading and sampling are continuous. In addition to being widely used in production processes, it is now widely used in laboratory equipment.

In the pharmaceutical industry, due to stricter requirements on production quality and production safety, the main process equipment for the production process of raw materials in centrifuges and other pharmaceutical production fields also has extremely high requirements. In addition to maintaining its own separation characteristics, centrifuges also need to meet the relevant specifications and standards in the medical field. Medicinal centrifuges need to consider materials, structures, material input and output methods, safety, labor intensity, control, cleaning or disinfection and sterilization from the perspective of meeting the requirements of the pharmaceutical production process.

The medical centrifuge has the requirements of cleaning and sterilizing when changing batches and changing varieties in production, preventing various pollution sources and avoiding re-contamination. The medical centrifuge needs to work hard in the aspects of automatic program control, human-machine isolation operation, easy cleaning, sterilizable and sterilizable structure, on-line analysis and separation and separation of different trait materials, improving function, control and sterilizing operation. Level.

Since the centrifuge in the medical field should be released from the drug, the surface of the centrifuge device must be smooth, flat, and free of dead angles. Therefore, it is necessary to ensure that the sharp corners, corners, and welds of the centrifuge are ground into a smooth transition circle during the manufacturing process. angle. Because of the need to make contact with the drug, the centrifuge needs to be resistant to corrosion, chemical changes or drug adsorption.

With the development of centrifuges, the technology related to centrifuges has improved. However, the pharmaceutical industry cannot be safer than the status quo and must continue to develop. With the support of national policies, centrifuge enterprises must continuously strive to promote the wider application of centrifuges in the pharmaceutical industry.

Latest Herexi News

- Hunan Herexi Join Hands The hunan science & equipment society

- Jinganzhang,I'm come; CISILE, I'm Here!

- Beijing Scientific instruments show & CISILE 2013 exhibition

- The training in Chengdu of Herexi series product

- The Algeria clients to visit centrifuge' production process of Herexi instrument

- Vacuum concentrator centrifuge celebrated the victory of China council for science association council board of directors

- High-speed centrifuge congratulations on successful launch of the shenzhou 10.

- analytica China at ShangHai 2014

- The world Unique Moisture Analyzer lunched

- Exhibition Announcement in the Second Half of 2016

Latest industry News

- Centrifuge rotor

- About the PRP centrifuge

- Laboratory Centrifuges

- Benchtop Centrifuges

- About the floor standing high speed centrifuge

- LCD centrifuge

- Oral special centrifuge/CGF centrifuge

- African swine fever centrifuge

- 5 Tips for Choosing the Right Centrifuge for your Lab

- The right choice of centrifuges, you can not ignore some of the problems!

kevin@hexiyiqi.com

kevin@hexiyiqi.com  0731-88142288

0731-88142288